Four critical steps to ensure the success of CCUS projects

Organisations globally are actively seeking to reduce their carbon footprints. In many locations, government entities provide tax incentives to meet carbon reduction targets or levy financial penalties for falling short. As a result, carbon capture, utilisation, and storage (CCUS) is gaining traction as a means of reducing emissions, with the global market estimated to hit $4 trillion by 2050.

Each CCUS project is unique, with its own barriers to success. Projects larger than 0.3MT of CO2 per year are particularly challenging, with 78% either cancelled or put on hold. Lack of subsurface understanding at the onset and neglecting to synchronise development and manage risk along the value chain can plague these projects and lead to failure. Multiple stakeholders, such as emitters, pore space owners, and service providers, must collaborate to minimise risk and ensure these highly complex and capital-intensive projects succeed. Site selection, waste stream processing, transportation, well design and construction, and monitoring are four critical steps that help determine CCUS project success.

CO2 storage site selection

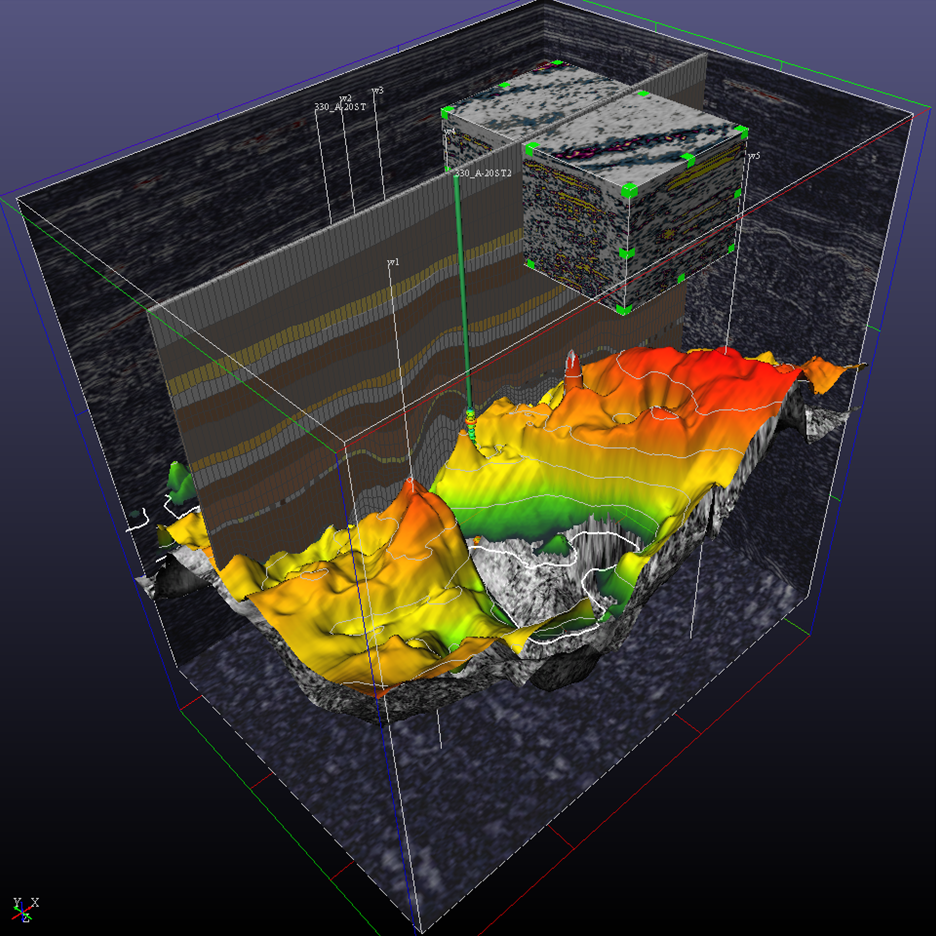

To start, a CCUS project needs a CO2 storage site and a long-term injection and storage plan. Project stakeholders must collaborate early in the planning stage to address subsurface unpredictability, which poses the highest technical risk. A site’s feasibility is determined by a range of characteristics, including capacity, injectivity, and containment. Whether onshore or offshore, it is imperative to have robust formation knowledge and integrate that data to develop stronger subsurface models as the projects mature.

This process starts by matching CO2 emitters to geological basins and then completing a deeper screening exercise and risk assessment to determine storage viability of selected aquifers, reservoirs, or fields. After selecting the site, organisations evaluate the subsurface with data from logs, physical core specimens, and water samples to determine depth, caprock thickness, lithology, porosity, and permeability. Drilling stratigraphic or monitoring wells near the planned injection site and wireline testing may be required to accurately model subsurface conditions and better understand injectivity and storage capacity.

Process and transport CO2 safely

After determining the storage site, a plan to process and transport the CO2 to the storage site is critical. This can be achieved via pipelines, trucks or even boats. The CO2 waste stream can undergo phase changes due to temperature and pressure fluctuations during transport. Unwanted contaminants and water in the waste stream can cause fouling and corrode transport system pipes and parts. Before transport, the waste stream requires drying and purification to remove water, nitrogen, hydrogen sulfide, heavy metals, and other contaminants. Chemical packages, pipeline monitoring, and booster stations can help meet requirements to transport CO2 safely.

Design and construct wells to store CO2

CO2 storage programs require reliable, high-integrity wells that meet regulatory requirements. Operations must be aligned to the well design plan to place and drill high-quality wells. This helps reduce collision risk with legacy wells, formation damage, and lost circulation events.

A CCUS project may require more than 30 years of harsh, cyclical injections, which underscores the importance of robust annular barrier designs. Wellbore cleaning before cement placement, centralisation to maximise radial annular coverage, and two-stage cementing operations ensure high-quality cement is placed over critical zones to help meet regulatory requirements and contain CO2 effectively. Long-term containment completions may require sub-surface safety valves, phase and flow back management tools, anchoring and isolation mechanisms, and sand control specifically designed for CCUS project.

Monitoring for long-term security

Even when injection is complete, a CCUS project is not: most projects require long-term monitoring for decades after injection ceases. Monitoring helps the operator manage the possibility of well integrity loss and fault or fracture reopening events that could lead to CO2 migration outside of the planned containment zone.

Each CO2 storage project requires a comprehensive measuring, monitoring, and verification (MMV) plan. Linking modeling to real-time monitoring and surveillance systems that integrate logging, fiber optics, and subsurface gauges facilitate early leakage detection and remediation.

Conclusion

While these four steps are critical, so is choosing the right partner for CCUS projects. Halliburton has more than 100 years of global oilfield services experience and leverages extensive knowledge in well construction, planning, and design to provide project leadership, subsurface evaluation, and risk assessment. This translates into safe and efficient CCUS technology deployment. Visit us in Hall 5, #5250 to learn more about Halliburton’s CCUS expertise.

KEEPING THE ENERGY INDUSTRY CONNECTED

Subscribe to our newsletter and get the best of Energy Connects directly to your inbox each week.

By subscribing, you agree to the processing of your personal data by dmg events as described in the Privacy Policy.