Integrally geared compressors cut the carbon and boost carbon capture

If the world is to move to a more sustainable future and hit net zero by 2050, industry needs to rapidly transition towards low carbon forms of energy production and industrial production. Recognising this, Atlas Copco Gas and Process created Cut the Carbon and put it at the heart of how we operate. Our machines play crucial roles in energy efficiency and are essential for industrial processes across the world, and they sit at the heart of the capture, use and storage (CCUS) of CO2.

Cut the Carbon

At Atlas Copco Gas and Process, we know that fundamental concerns about our planet need to lead to concrete action on climate change. And if the low carbon transition is to succeed, our technological innovations and know-how need to be in step with sustainable practices. As well as working with highly efficient industrial heat pumps, creating hydrogen solutions, and ensuring our machines receive first-class revamps and upgrades, our technology is also making a real impact in CCUS.

Though still an emerging field, the capture, use and storage of CO2 is becoming an increasingly important factor in the energy industry and in hydrocarbon processing. This can be seen with the 45 commercial CCUS facilities already operating worldwide, and the fact that, according to the IEA (International Energy Agency), there are hundreds of projects “in various stages of development across the CCUS value chain”. There is significant potential for CO2 capture in the cement and steel industries, as well as at hydrocarbon facilities, such as gas processing, power generation, synfuel, and hydrogen production.

Compression technology & CCUS

CCUS facilities rely on high-quality, reliable compression technology. Once captured, CO2 can be used on site, or it can be compressed and transported via pipeline, rail, road (trucks) or ships to be used in a range of applications. Otherwise, it can be stored deep underground (such as in saline aquifers, or oil or gas reservoirs).

Underpinning the development of major CCUS projects has been the capability of integrally geared centrifugal turbocompressors to effectively perform CO2 duty. Atlas Copco Gas and Process know-how in the field has been built on decades of experience in chemical, petrochemical, and CCUS processes. We developed our technology from initially working with low and medium-pressure applications up to higher pressures of 100 and 200 bar (and above).

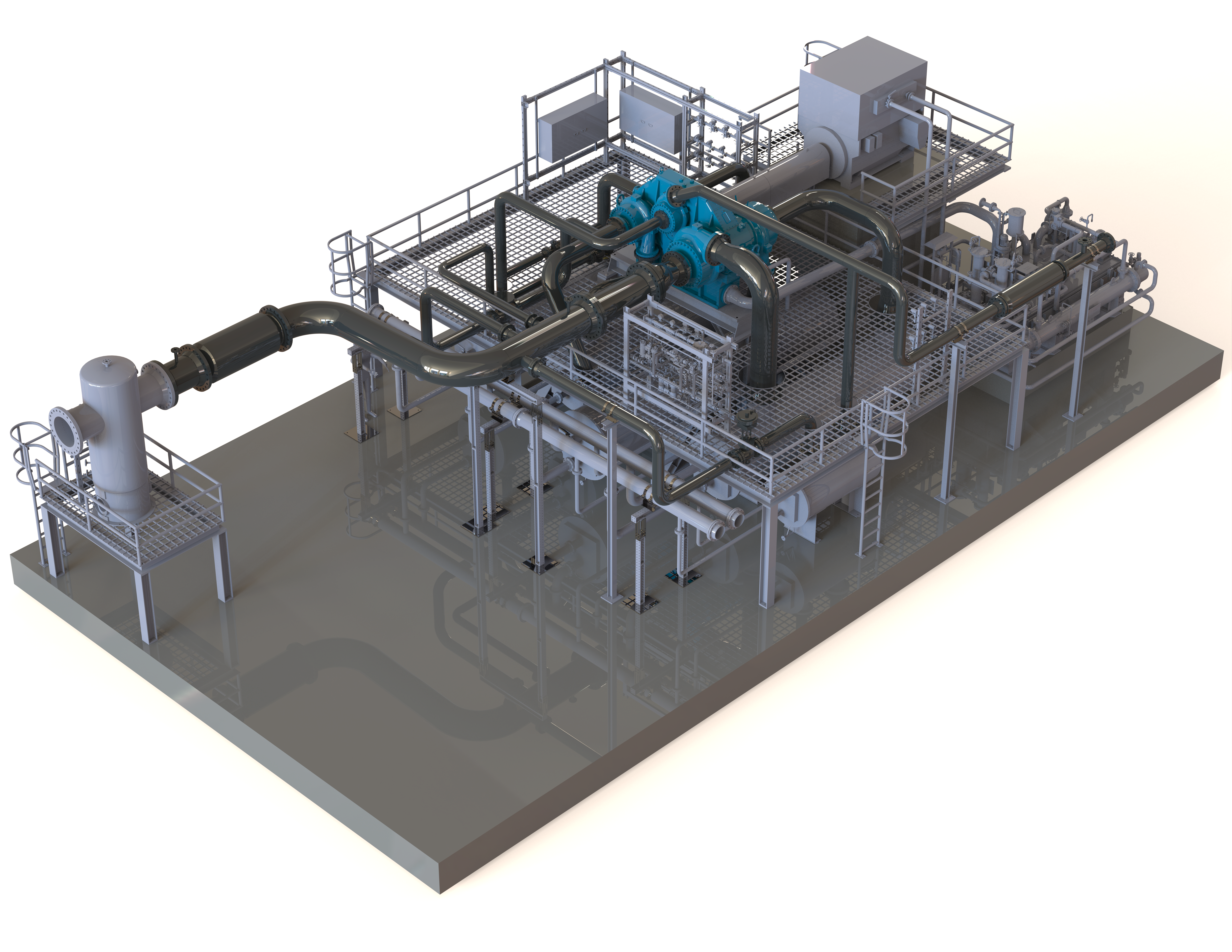

Nowadays, integrally geared compressor (IGC) technology is a well-established, highly efficient, and reliable method of compressing CO2. And there are several reasons why our integrally geared compressors work so well with CO2 compression: their capacity to adapt rotor speed in one or more pair of stages, which provides increased efficiency. In addition, our IGCs have the advantage of combining the gearbox, lube oil system, and all the compression stages onto a single skid unit.

Flexibility is built into all our IGC designs. Not only does every impeller in effect become its own stage but it has its own casing, with its own inlet and discharge connections. The benefit of fewer impellers, however, is not just confined to speed, or efficiency and performance: the benefits can also be seen in a lower footprint and lower capex.

With a demanding and challenging gas such as CO2, it is critical that leakages are kept to an absolute minimum. Our specially designed carbon ring seals, dry gas seals, and seal support systems are central factors in ensuring that IGCs work well with CO2. Our machines are also designed to have intercooling between stages, with a concomitant increased flexibility, more efficient compression, and minimized maintenance requirements. In addition, our compact modular and flexible IGC designs have a small footprint at the same time as delivering maximum efficiency.

Trusted and reliable partners

Atlas Copco Gas and Process provides both modular and customized solutions for CCUS applications, with our customers’ requirements central to machine designs. With more than 30 successful CCUS applications already installed, our customers embrace us as trusted, reliable partners. They also place great value on our global footprint, which means local manufacturing and comprehensive aftermarket support.

The climate emergency is driving forward solutions that will help reduce carbon emissions. Though still an emerging field, the capture, use and storage of CO2 is increasingly becoming part of hydrocarbon processing and the energy industry. Our integrally geared machines maximize CCUS efficiency, creating significant energy savings.

Energy Connects includes information by a variety of sources, such as contributing experts, external journalists and comments from attendees of our events, which may contain personal opinion of others. All opinions expressed are solely the views of the author(s) and do not necessarily reflect the opinions of Energy Connects, dmg events, its parent company DMGT or any affiliates of the same.