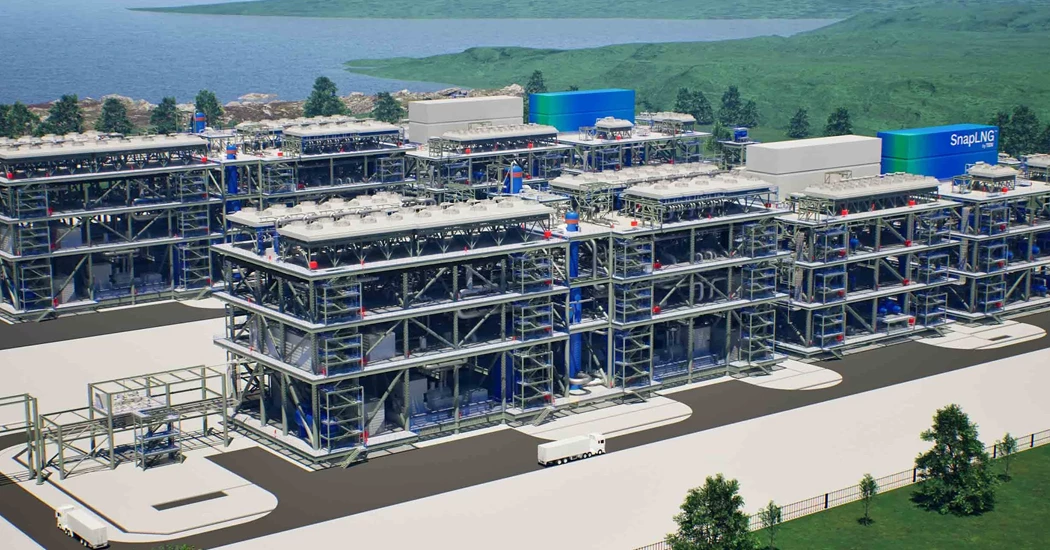

Technip Energies pioneers LNG decarbonization with its SnapLNG by T.EN™ solution

SnapLNG by T.EN™, the solution zero for low carbon LNG Pioneered to a large extent by the LNG industry, large-scale modularization of process plants has strongly expanded in the past 15+ years. Problems with construction in high-cost OECD countries, the development of FLNG, and the long search for a viable method of developing liquefaction facilities in harsh environments like within the Arctic Circle have all pointed to modularization.

This created an enthusiastic investment climate on all continents and there are now several operating facilities that demonstrate this approach. However, attention to “economy of scale” has yet to be fully exploited to ensure that LNG train size remains within modularization constraints boundaries, including optimized module fabrication sequence, offshore and onshore transportation, and site installation.

Technip Energies provides SnapLNG by T.EN™, a solution that offers significant advantages in terms of time-to-market, cost certainty and execution risk reduction. As our “Solution Zero” for low-carbon LNG, SnapLNG by T.EN™ integrates the latest technologies and equipment with full digitalization, ensuring highly efficient and reliable plant operation and maintenance as well as low carbon emissions.

The optimized modularization approach not only maximizes activities at fabrication yards to minimize on-site activities, but also allows to perform all the Blue power at the horizon and most of the commissioning activities before modules are shipped to site. Technip Energies proposes a pre-engineered and tangible product with the main advantage of significantly shortening the overall execution schedule compared with the usual project development phasing from feasibility study to the end of the modules’ engineering, procurement and fabrication (EPF).

State-of-the-art low-emission LNG plant

SnapLNG by T.EN™ addresses environmental imperatives through specific design features that limit hydrocarbon and chemical gas emissions, mainly methane, carbon dioxide and volatile organic compounds (VOCs), and through systematic measures to detect fugitive emissions and repair them (LDAR). We implement strategies to limit CO2 emissions from process and utility units during normal continuous operations, normal transient operations and abnormal phases, and from specific c identify ed pieces of equipment and bulk materials.

Our solution also enables companies to meet local regulatory requirements and to produce the low-carbon LNG expected from countries and utilities distribution companies. Overall, it avoids about 350 KT equivalent per year of CO2 emissions per 2.5 MTPA train. This aligns with the global LNG trend to produce low-carbon LNG, particularly by developing electrified LNG plants.

By adopting SnapLNG by T.EN™, companies can confidently navigate the evolving regulatory landscape and contribute to the global effort to reduce carbon emissions in LNG production.

SnapLNG by T.EN™ main technical features

The technical aspects of SnapLNG™ by T.EN have been secured through the development of a robust and reliable FEED design based on T.EN’s experience in modularized LNG plants delivery across the world:

- A nominal plant capacity that is as large as possible to bring economies of scale, but suited to allow complete systems to be included in single modules allowing pre-commissioning at the module fabrication yard and minimizing hookup work on site.

- Three utility modules supporting the operation of the process train already pre-engineered, including the flare knockout drum module, plant air and nitrogen module and chilled water and hot water module.

- A fully electrified design to essentially eliminate greenhouse gas emissions.

- Air Products AP-DMR liquefaction process, perfectly suited for such capacity, most effi cient in energy consumption and easiest to modularize due to a low equipment count.

- Electric motor drivers for refrigeration compressors of around 50 MW as these motors have sound industrial references in operation.

- Module sizing i.e. dimensions and weights, compatible with the constraints of sea and on-land transportation.

- Self-functional modules to maximize activities at module fabrication yards. The design considers the full integration of the refrigerant compressors into the liquefaction modules at the yard.

- Extensive use of digital solutions, including digitalization of data management for the FEED and identification and description of project tested digital solutions for the EPF phase.

- Identification of environmental solutions to limit and detect GHG (Greenhouse gas) and VOC emissions.

Accurate and dependable EPF cost estimate

A full-cost estimate of the modules is developed based on market inquiries for the most critical pieces of equipment and module fabrication.

Blue power at the horizon

As an alternative to renewable power, Technip Energies is offering the possibility of using an industrially proven combined cycle power plant equipped with post-combustion carbon capture for which technology is commercially available. In a nutshell, SnapLNG by T.EN™ represents a significant milestone, offering a cutting-edge solution for low-carbon LNG production that can address the industry’s future challenges.

Energy Connects includes information by a variety of sources, such as contributing experts, external journalists and comments from attendees of our events, which may contain personal opinion of others. All opinions expressed are solely the views of the author(s) and do not necessarily reflect the opinions of Energy Connects, dmg events, its parent company DMGT or any affiliates of the same.